We’re answering the call to create an economically and environmentally resilient future for our nation through additive manufacturing and innovative, sustainable materials technologies.

The AM2 Tech Hub will establish Virginia’s New River Valley and Southern Virginia regions as a global destination and home for industry additive manufacturing and advanced materials solutions, where manufacturers can find technological pathways towards secure, resilient, agile, and innovative supply chains.

We are currently developing strategies and implementation projects meant to mobilize ecosystem resources and support company development and growth. Priority projects include:

We facilitate access to AM2 Intellectual Property and assist business startups interested in growing and using this technology.

We create and support talent

skilled in AM2 and other technologies needed to support the future of manufacturing.

We help existing businesses, small and large, grow through AM2 technology adoption and technical assistance.

Our events and meetings are open to interested

partners. Please fill out the RSVP Request form

below to receive more information.

Volvo Trucks has long been a transportation leader in advanced manufacturing and additive materials. Stationed in Greensboro, Volvo’s CampX program is fostering the next round of innovation in transportation by creating a collaborative environment where startups, industry partners, and Volvo’s teams work together, providing access to resources, expertise, and mentorship. Businesses develop and test emerging technologies like electromobility, connectivity, and autonomous driving. CampX accelerates the commercialization of new solutions that address key industry challenges through agile development practices, innovation challenges, and events.

GENEDGE’s Reconfigure Virginia’s Manufacturers for Modernization Program (Re-VAMMP) aims to boost the adoption of metal additive manufacturing (AM) among small and medium-sized machine shops in Virginia’s defense industrial base. Partnered with Virginia Tech and supported by the U.S. Department of Defense, the program addresses supply-chain bottlenecks and reliance on legacy systems that hinder innovation. Through education workshops and technical assistance, Re-VAMMP focuses on reducing production costs for manufacturers and securing the defense supply chain.

GO TEC (Great Opportunities in Technology and Engineering Careers) aims to build an education pipeline of in-demand skills, like those in additive manufacturing and advanced materials, by providing hands-on training and career exploration opportunities in various STEM fields to middle school students. The curriculum includes modules in fields such as electrical engineering, additive technologies, IT coding, welding, and fields important to additive manufacturing and advanced materials. Students participate in hands-on learning experiences, often using advanced equipment like virtual reality welding simulators, CNC machines, 3D printers, and laser cutters. GO TEC has programs in 25 middle schools across Virginia. The program plans to reach 50 schools by 2025, covering Southwest Virginia, Central Virginia, and the greater Hampton Roads area.

Led by the Virginia Manufacturers Association, the Manufacturing Skills Institute (MSI) offers industry-approved certifications and real-world experience that prepares individuals for successful careers in advanced manufacturing. These certifications are developed with industry experts and employers to ensure they align with current market demands and provide participants with relevant skills and knowledge. MSI certifications are accessible through various formats, including online courses and partnerships with educational institutions, making them available to a wide audience. The MSI program is already working with several community colleges and high schools in the AM2 Tech Hub footprint, as well as connecting workers with 20+ regional manufacturers.

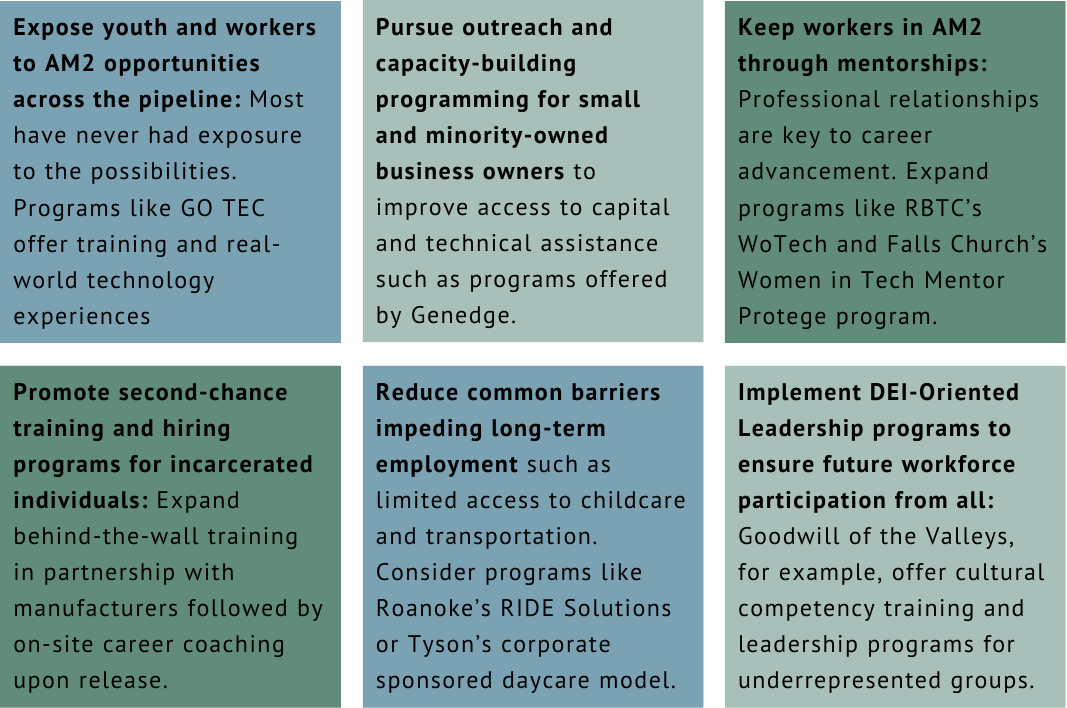

In Spring 2024, the Economic Development Studio at Virginia Tech—made up of eight graduate students—considered strategies to build a robust additive manufacturing and advanced materials ecosystem by integrating technology-based economic development with approaches to inclusive development. During this semester-long course, students reviewed economic development strategies, interviewed local stakeholders, and identified local and national cases with promising inclusive practices. Students found that the AM2 Tech Hub should work with its ecosystem of partners to:

For more information, contact Sarah Lyon-Hill, sarahlh@vt.edu.

The AM2 Tech Hub team hosted a webinar in July, which examined the broad spectrum of “advanced materials”. Key panelists were Dr. Robert Moore, the Director of the Macromolecules Innovation Institute at Virginia Tech; Vince Hatcher, the Director of Operations for the Americas at Hollingsworth & Vose; and Dominic Allen, the Chief Commercial Officer at IperionX.

Source: Virginia Tech

A consortium led by the New River Valley Regional Commission has been selected for a highly competitive $500,000 federal Tech Hubs Strategy Development Grant . . .

Source: Cardinal News

Cardinal News recently reported that a consortium based in the New River Valley, in partnership with Danville and Southern Virginia organizations, plans to. . .

Source: Virginia’s New River Valley

WSLS Channel 10 recently reported that Governor Youngkin announced $1.9 million in GO Virginia grants for eight different programs. These projects help . . .

Source: GO Virginia Region 2

NRV Materials and Machinery Cluster Scale-Up will convene regional partners and develop a 10-year roadmap for supporting materials and machinery scale-up in the New River Valley . . .

Source: Cardinal News

The United States Navy is expanding its presence in Danville.

An existing Navy pilot program focuses on developing a new workforce for shipbuilding at Danville’s Institute. . .

Source: MELD Manufacturing

MELD Manufacturing announces that it has been awarded a $975 million contract by the United States Air Force to support the Rapid Sustainment Office (RSO) in optimizing the operational readiness of deployed assets.

This significant contract recognizes MELD’s advanced capabilities in additive manufacturing and its vital role in advancing manufacturing processes within the aerospace and defense sectors. MELD is among 67 companies awarded contracts. . .

Source: Office of the Governor

Governor Glenn Youngkin announced that TECHnista, LLC, an education consulting company specializing in curriculum development for K-12 programs in defense and advanced manufacturing industries, will invest $1,559,646 to establish its National Training and Technology Center in Pittsylvania County.

The project will create 15 new jobs and support the implementation of a five-year federal contract with the U.S. Department of Defense’s office of Innovation Capability and Modernization. Virginia successfully competed with North Carolina for the project.. . .

How can we best collaborate to support and grow advanced

manufacturing in Virginia and the United States at large?

Let’s make additive manufacturing and advanced materials technologies easier to commercialize and grow entrepreneurial startups around these technologies!

We are pulling together existing programs and generating new activities that increase the transparency of the process and support those wanting to take technology to market. Let us know how we can help.

Let us help you develop, attract, and retain qualified workers specialized in additive manufacturing and advanced materials!

By tying together existing, best-practice programming and developing new talent activities, we are developing a pipeline of talent in this region meant to support America’s advanced manufacturing. Let us know how we can help.

Let’s accelerate, grow, and take America’s manufacturing to the next level!

We provide technical assistance to existing businesses throughout their lifecycle, from small manufacturers of 2-5 employees to internationally ranked manufacturing titans. We support those wanting to adopt AM2 technologies, strengthen their supply chains, and/or grow their operations in Southern and Southwest Virginia. Let us know how we can help.