Press release courtesy of MELD Manufacturing — MELD Manufacturing announces that it has been awarded a $975 million contract by the United States Air Force to support the Rapid Sustainment Office (RSO) in optimizing the operational readiness of deployed assets. This significant contract recognizes MELD’s advanced capabilities in additive manufacturing and its vital role in advancing manufacturing processes within the aerospace and defense sectors. MELD is among 67 companies awarded contracts for the same funding, collectively supporting the Air Force’s Rapid Sustainment Office in advancing critical sustainment capabilities.

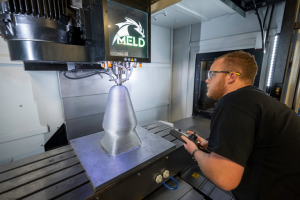

The RSO, focused on enhancing readiness and sustainability across the U.S. Air Force, has selected MELD for its solid-state metal additive manufacturing process. MELD’s technology enables the production of large-scale components using aerospace-grade materials, delivering exceptional results. The company has successfully printed flight-critical components, achieving forging-level quality with materials such as Al-7075, Al-6061, and Ti-64.

This contract is in addition to the DoD and DoE investment in MELD machines. To date, the U.S. Army, Air Force, NAVAIR, and NAVSEA have invested in MELD technology with the acquisition of multiple L3, K3, and CD-14 machines to support various government initiatives. MELD has been integral to critical U.S. Air Force projects, with the Air Force acquiring MELD machines and employing MELD technology in the development of UAV airframes. Notably, MELD is the only large-scale, solid-state metal 3D printer chosen by the RSO and the only company with additive technology both invented and manufactured in the United States. A complete list of the awarded companies can be found here.

About MELD Manufacturing:

MELD Manufacturing Corporation offers groundbreaking 3D printing and hybrid machines designed for metal additive manufacturing using the proprietary MELD process. Their printers accommodate volumes as large as four meters wide, two and half meters deep, and one meter high, with custom integration services available for even larger print volumes. The MELD process, a revolutionary solid-state technology with over 20 patents, enables the additive manufacturing of metal parts without melting the material. Operating in an open atmosphere, MELD’s process allows for the production of large metal components at a scale and speed unmatched in the metal additive market. MELD Manufacturing is committed to disrupting traditional metal manufacturing and repair processes, both on Earth and in space, by leveraging the power of 3D printing. With its award-winning, patented technology, MELD aims to deliver reliable equipment capable of printing in any metal, at any size, and at unsurpassed speeds, all while maintaining forged properties. For more information about MELD Manufacturing Corporation and the AFSD process, please visit www.meldmanufacturing.com.